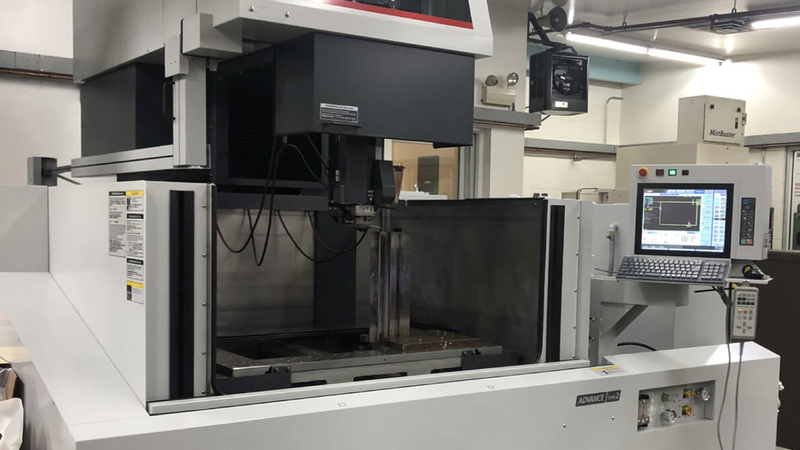

In the realm of CNC machining, the evolution from 3-axis to 5-axis technology marks a significant leap. At Brodeur Machine Co., a precision CNC machining company based in New Bedford, MA, we’ve mastered this evolution. Our journey from a humble garage to a 58,000 square foot state-of-the-art facility reflects our commitment to adopting advanced machining techniques, including the sophisticated 5-axis CNC machining.

The Basics of CNC Machining Axes

Understanding the axes in CNC machining is fundamental. Traditionally, machining relied on the 3-axis system – X, Y, and Z. These axes represent the primary directions of movement a tool can make in a workpiece. Transitioning to 5-axis machining opens up new possibilities, adding two additional axes of rotation, which we will delve into.

The First Three Axes: X, Y, and Z

At Brodeur Machine Co., precision starts with mastering the basic three axes. The X-axis signifies horizontal movement, the Y-axis vertical, and the Z-axis depth movement. Mastery of these axes allows for precise cutting across various dimensions.

The Fourth Axis: A-Axis

The introduction of the A-Axis, which allows rotation around the X-axis, propels our machining capabilities into a more advanced realm. This axis enables us to approach the workpiece from various angles, allowing for more complex geometries.

The Fifth Axis: B-Axis or C-Axis

Our 5-axis CNC machines are equipped with either a B-Axis, which provides rotation around the Y-axis, or a C-Axis, offering rotation around the Z-axis. This addition facilitates the machining of intricate and sophisticated designs with unparalleled precision.

Advantages of 5-Axis CNC Machining

The benefits of 5-axis machining at Brodeur Machine Co. are manifold. It enhances precision, allows the creation of complex shapes, and improves surface finishes while reducing setup time. This translates to increased efficiency and superior quality in our production.

Applications in Various Industries

5-axis machining is pivotal in industries demanding high precision and intricate designs, such as aerospace, automotive, and medical device manufacturing. At Brodeur Machine Co., we leverage this technology to meet the intricate needs of these sectors, producing components that adhere to the most stringent standards.

Considerations When Using 5-Axis CNC Machining

Selecting the right machine and setting it up optimally are crucial. Our team at Brodeur Machine Co. focuses on programming accuracy and optimal toolpath strategies to maximize the potential of 5-axis machining.

Challenges and Solutions in 5-Axis Machining

While 5-axis machining offers numerous benefits, it also presents unique challenges, such as tool interference and complex programming requirements. Our skilled machinists and programmers at Brodeur Machine Co. excel in troubleshooting these challenges, ensuring seamless operations.

The Future of 5-Axis CNC Machining

The future of 5-axis CNC machining is promising, with continuous technological advancements anticipated. At Brodeur Machine Co., we stay at the forefront of these innovations, ensuring our services remain cutting-edge.

Conclusion

5-axis CNC machining represents the pinnacle of machining precision and complexity. At Brodeur Machine Co., our expertise in this area ensures that we deliver only the highest quality parts and components. Our commitment to innovation and quality makes us a trusted partner in the CNC machining industry.

For inquiries or to learn more about our 5-axis CNC machining capabilities, contact Brodeur Machine Co. at 508-995-2662. Let us be your partner in navigating the complexities of advanced CNC machining.