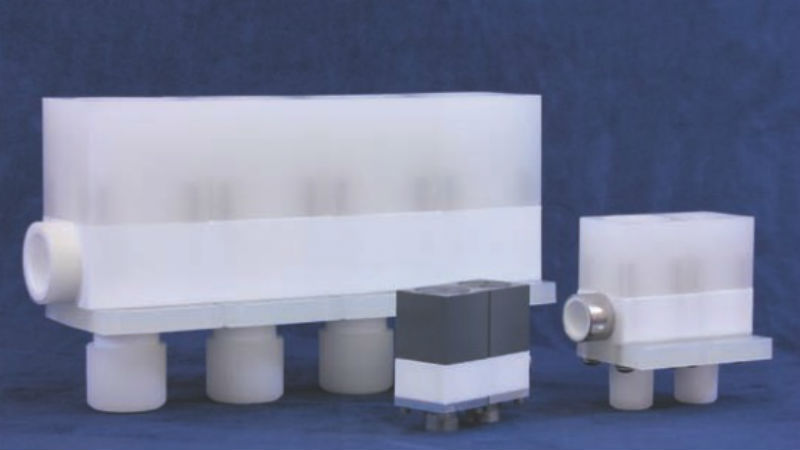

When it comes to valves, there are standard options, sizes, and materials, there are high purity valves, and then there are special valves. Some companies are able to also offer customized valves to meet specific requirements for a given application. This customization can include unique or unusual configurations for the valve, often allowing for the replacement of an existing customized valve without the need to reconfigure the entire system.

Materials to Consider

One of the most common materials to use in the manufacturing of valves is polypropylene. These polypropylene valves can be found in standard types of systems including plumbing, water systems, and other types of similar applications. They can also be used in specialized applications including as diverter valves or quick dump valves.

It is also possible to create a high purity valve from polypropylene valves. To meet the standards set, the wetted areas of the valve are manufactured from PTFE, also known by the commercial name of Teflon. The external components, which do not make any contact with the media, can be made from polypropylene or other materials.

Types of Valves

It is possible to have almost any type of polypropylene valves. Depending on the needs of the system, from on and off control to metering or controlling of the flow of the media, it is possible to choose ball, stopcock, metering, plug or check valves.

Choosing the specific type of valve is dependent on the role of the valve in the system as well as if it will be manually controlled, pneumatically controlled or if it is to operate fully automatically, as in the case of the check valve.

In some cases, more than one type of valve may be a suitable option. In these situations, considering the benefits and possible challenges in using all possible valves can help to narrow down the choices.